Editor-reviewed by Ahmad Zaidi based on analysis by TransforML's proprietary AI

CEO, TransforML Platforms Inc. | Former Partner, McKinsey & Company

How are life science leaders like Thermo Fisher and Danaher deploying AI and operational business systems to improve laboratory productivity?

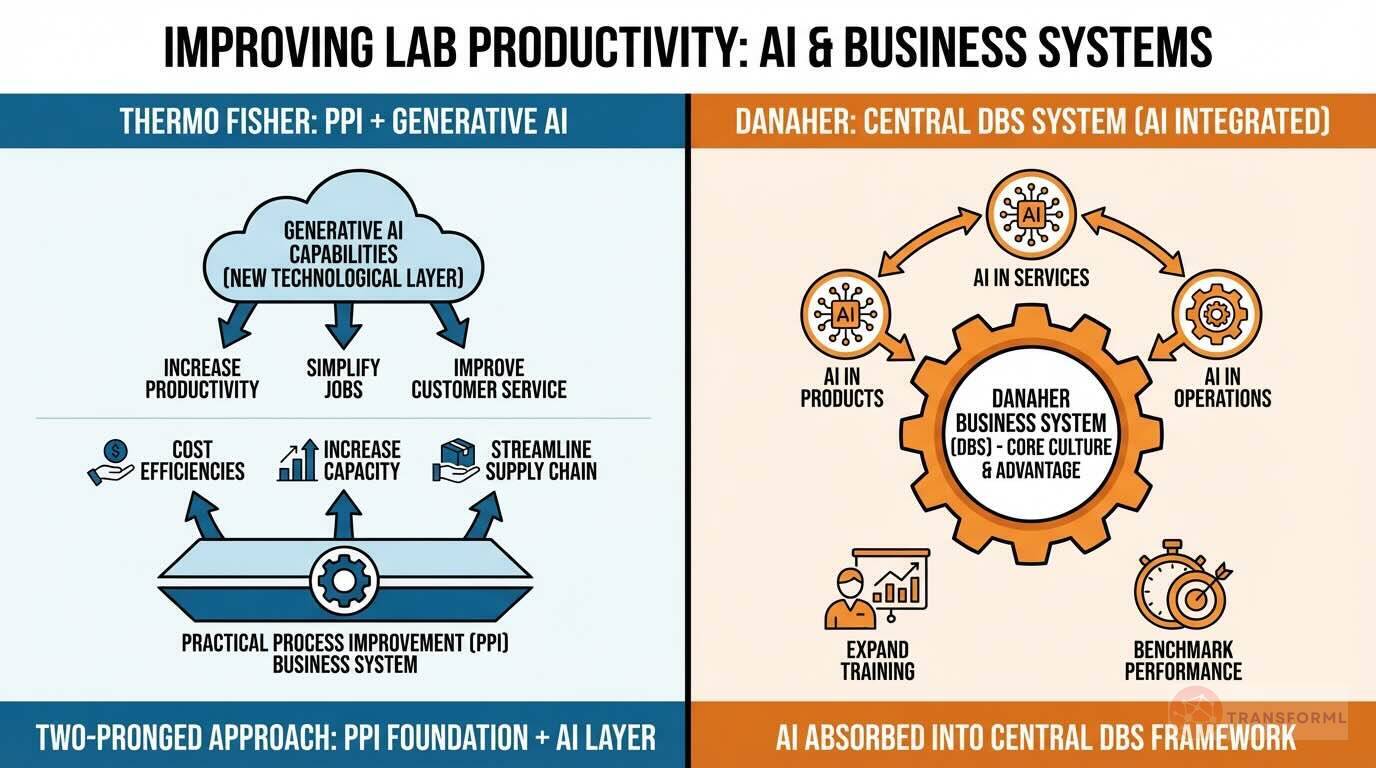

Thermo Fisher employs a two-pronged approach to enhance laboratory productivity, combining its long-standing operational system with emerging technology. The foundation is its "Practical Process Improvement (PPI) Business System," a methodology used across the company to improve cost efficiencies, increase capacity, and streamline supply-chain performance. More recently, Thermo Fisher has begun to "Leverage generative artificial intelligence capabilities" as a distinct initiative. This is aimed at increasing productivity, simplifying jobs for employees, and improving customer service, representing a new technological layer on top of their established PPI framework.

Danaher's approach is distinguished by the absolute centrality of its "Danaher Business System (DBS)," which is positioned not just as a tool, but as the company's core culture and primary competitive advantage. All operational improvements and efficiency gains are driven through DBS, with specific goals to expand training and benchmark performance. Danaher's deployment of AI is framed as an "integration of Artificial Intelligence (AI) into Danaher's products, services, and operations." This suggests that AI is not a separate initiative but is being absorbed into the all-encompassing DBS framework to further drive innovation and efficiency, both internally and within the products it sells to customers.

Review detailed strategy and competitive analysis of companies in Life-Science Tools & Diagnostics

Source and Disclaimer: This article is based on publicly available information and research. For informational purposes only (not investment, legal, or professional advice). Provided 'as is' without warranties. Trademarks and company names belong to their respective owners.