Editor-reviewed by Ahmad Zaidi based on analysis by TransforML's proprietary AI

CEO, TransforML Platforms Inc. | Former Partner, McKinsey & Company

How are industrial leaders like Honeywell, Eaton, and Siemens using AI and IoT platforms to build the smart factories of the future?

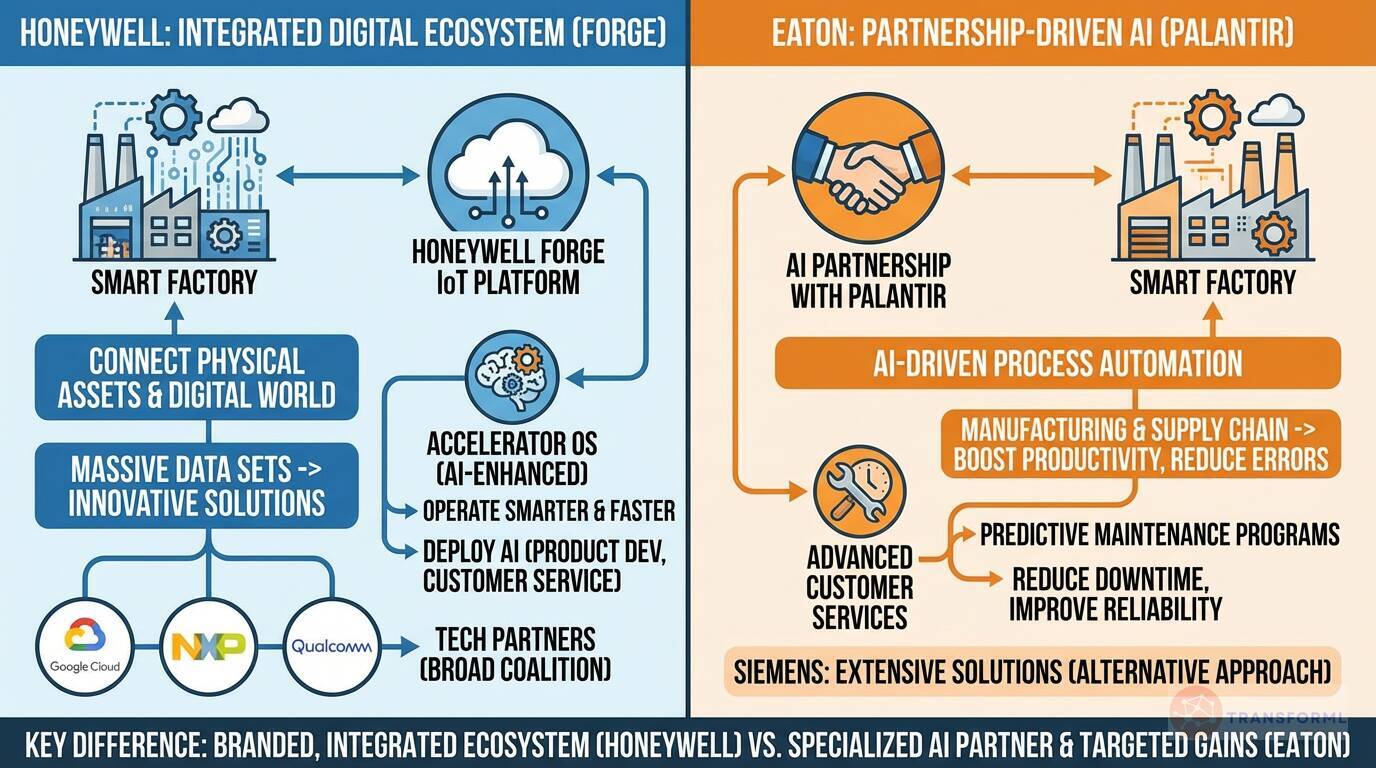

Industrial leaders are moving beyond selling standalone hardware and are now building comprehensive digital ecosystems to power the smart factories of tomorrow. Honeywell is a prime example, centered on its proprietary Honeywell Forge IoT platform. The company's strategy is to "Drive adoption of Honeywell Forge" to connect physical assets with the digital world, using the massive data sets generated to deliver innovative solutions. Internally, Honeywell is enhancing its "Accelerator" operating system with AI to "operate smarter and faster" and is deploying AI across functions like product development and customer service to drive efficiency and growth. This platform-based approach is supported by a broad coalition of technology partners, including Google Cloud, NXP, and Qualcomm.

Eaton is pursuing a similar goal through a different path, focusing on a deep technology partnership with Palantir to deploy its AI platform. This collaboration aims to "Implement AI-Driven Process Automation" across Eaton's manufacturing and supply chain functions to boost productivity and reduce errors. For its customers, Eaton is leveraging AI and data analytics to offer advanced services like "Predictive Maintenance Programs," reducing downtime and improving equipment reliability. While competitors like Siemens also offer extensive industrial solutions, the key difference lies in the approach: Honeywell is building a branded, integrated digital ecosystem (Forge) for broad application, whereas Eaton is leveraging a specialized AI partner for more targeted operational and customer-facing efficiency gains.

Review detailed strategy and competitive analysis of companies in Industrial Automation & Controls

Source and Disclaimer: This article is based on publicly available information and research. For informational purposes only (not investment, legal, or professional advice). Provided 'as is' without warranties. Trademarks and company names belong to their respective owners.