Editor-reviewed by Ahmad Zaidi based on analysis by TransforML's proprietary AI

CEO, TransforML Platforms Inc. | Former Partner, McKinsey & Company

How are Applied Materials, Lam Research, and KLA using materials engineering, etch, and process control to power the AI revolution?

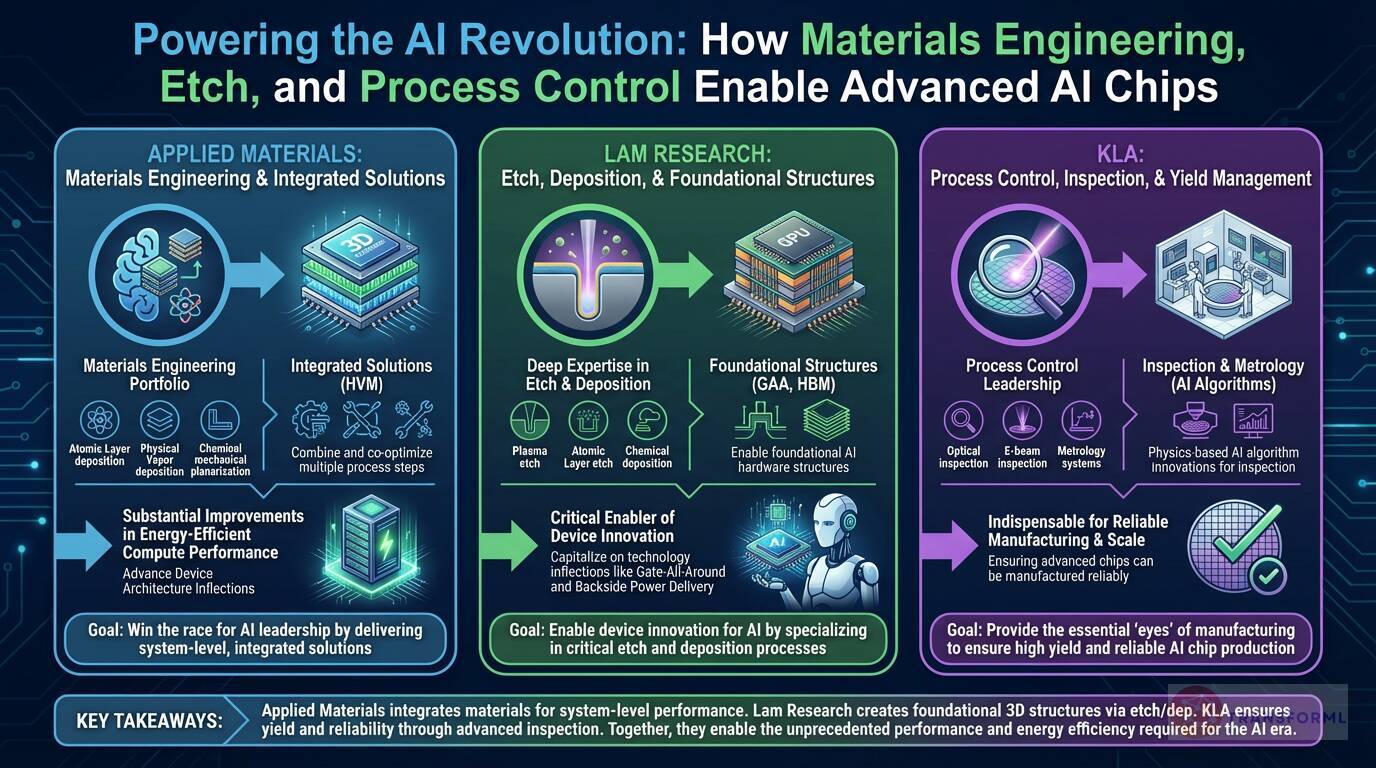

The AI revolution demands chips with unprecedented performance and energy efficiency, pushing manufacturers toward complex 3D architectures and new materials. Applied Materials, Lam Research, and KLA are all critical enablers in this transition, but they attack the problem from different angles. Applied Materials leverages its broad "materials engineering" portfolio to help customers "win the race for AI leadership" by delivering "substantial improvements in energy-efficient compute performance." This holistic approach allows them to combine and co-optimize multiple process steps to solve system-level challenges. In contrast, Lam Research focuses its deep expertise in "etch and deposition" to enable the foundational structures of AI hardware, such as GPUs and high-bandwidth memory.

Each company's specific goals reflect their unique contribution to the AI ecosystem. Applied Materials aims to "Advance Device Architecture Inflections" to provide integrated solutions for the complex demands of AI chips. Lam Research, the specialist, is a "critical enabler of the device innovation" for AI by capitalizing on specific "technology inflections like gate-all-around" and "backside power delivery." Meanwhile, KLA provides the essential "eyes" of the manufacturing process. As AI chips become more intricate, the risk of yield-killing defects rises. KLA's leadership in "process control" and its development of "physics-based AI algorithm innovations" for inspection are indispensable for ensuring these advanced chips can be manufactured reliably and at scale.

Review detailed strategy and competitive analysis of companies in Semiconductor-Equipment Makers

Source and Disclaimer: This article is based on publicly available information and research. For informational purposes only (not investment, legal, or professional advice). Provided 'as is' without warranties. Trademarks and company names belong to their respective owners.